Process doors, vertical doors, sliding doors & turntable doors

As safe as the cabinIn order for work inside of a laser enclosure to take place in a safe manner without delays, the components to be processed must be fed in and out of the booth’s interior without any problems. This is exactly what our process, lifting, and sliding doors ensure. Our door designs are modular and can be installed in virtually any size or location to fit your specific needs.

Products

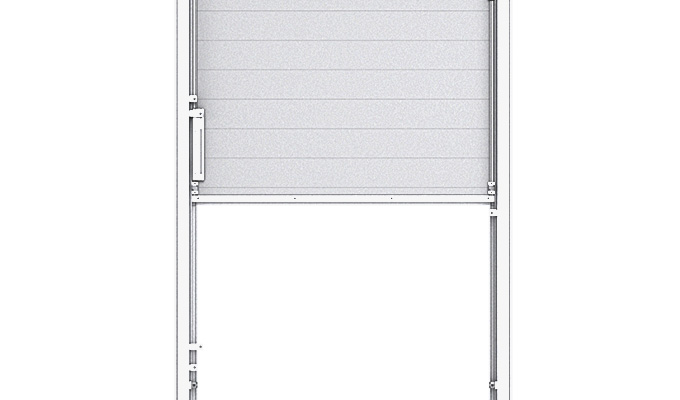

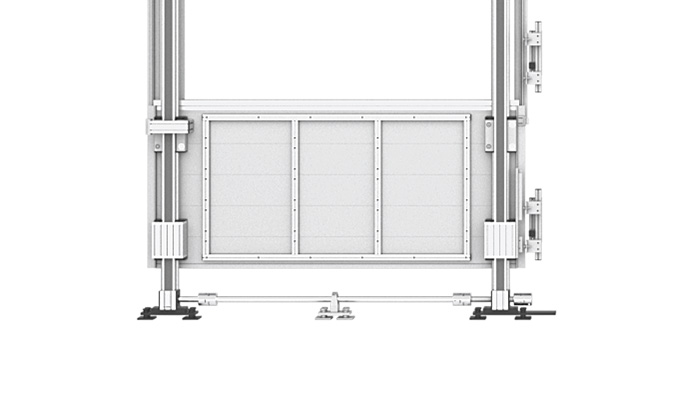

Thanks to the profiles used, the vertical process door is absolutely light tight. Stray laser beams run themselves dead in the labyrinthine structure and cannot cause any damage outside the booth. The motor connection for opening and closing the door can be made either at the top or at the bottom, depending on the intended use. Safety is insured through a counterweighted door design, and optional shot pins.

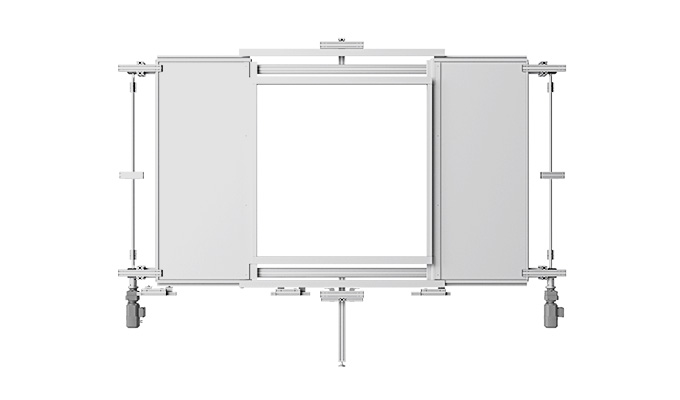

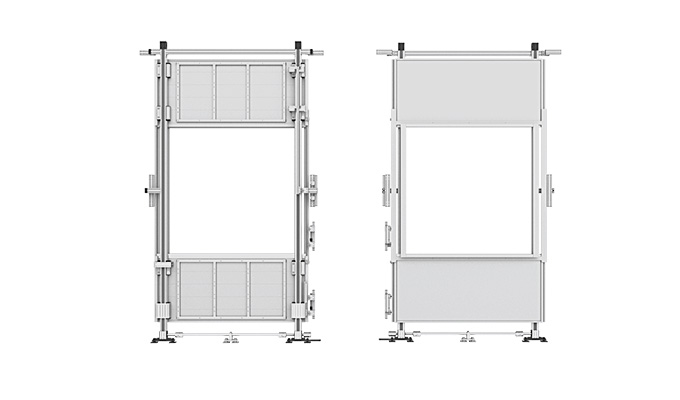

A horizontal rolling process door is mainly used when process flows or space conditions require it. Because of the shorter travel distance required by the split door design, these process doors are able to open and close faster than most other solutions. Most applications require less than 3 seconds for opening and closing.

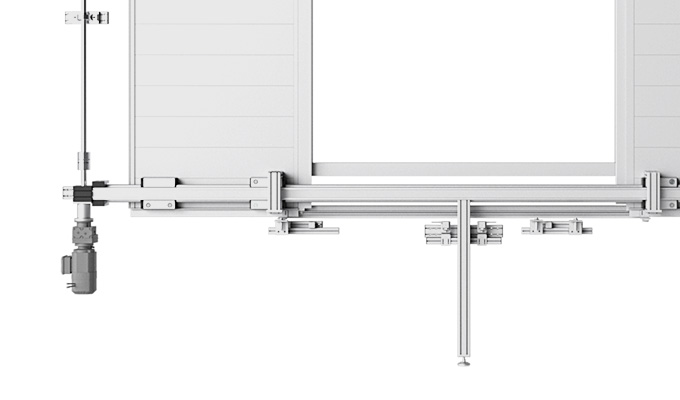

To move a vertical rolling process door, unlike the vertical process door, no counterweight is needed. The motor only has to overcome the friction and inertia of the door, which is why this door can be operated in a very energy-efficient manner. Additionally, due to the shorter travel distance required by the split door design, these process doors are able to open and close faster than most other solutions. Most applications require less than 3 seconds for opening and closing.

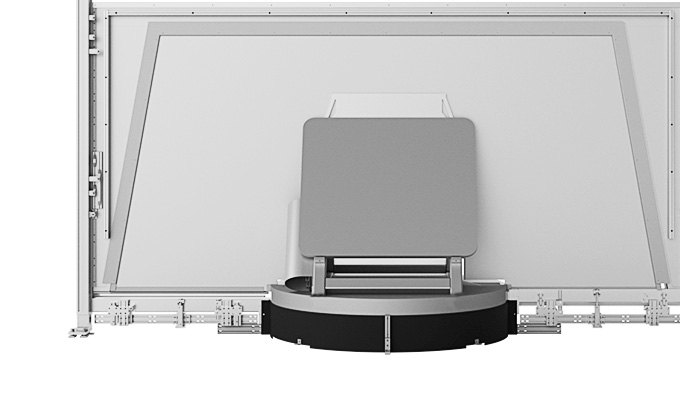

We supply double-acting lift gates, cladding for rotary tables and complete rotary systems for uninterrupted laser use.

Contact now

Always up to dateDo you have a question? A suggestion? Or an order? Don’t hesitate to get in touch with us. Whether by e-mail or with a phone call – our experts will be happy to help you with all aspects of aluminium profiles.