Belt driven linear systems

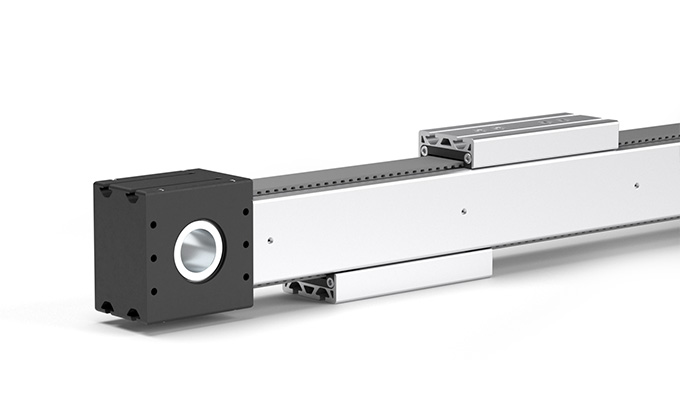

When high speeds and long travel distances are required, toothed belt driven linear systems are ideally suited for your material handling and positioning tasks. Toothed belt driven linear systems are easy to incorporate into single or multi axis systems and offer long service life with minimal noise and maintenance.

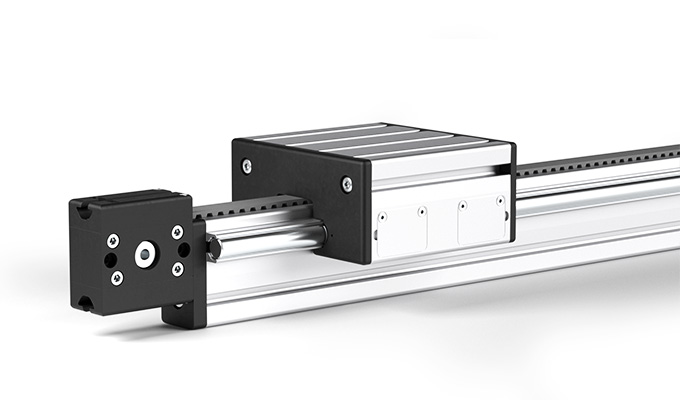

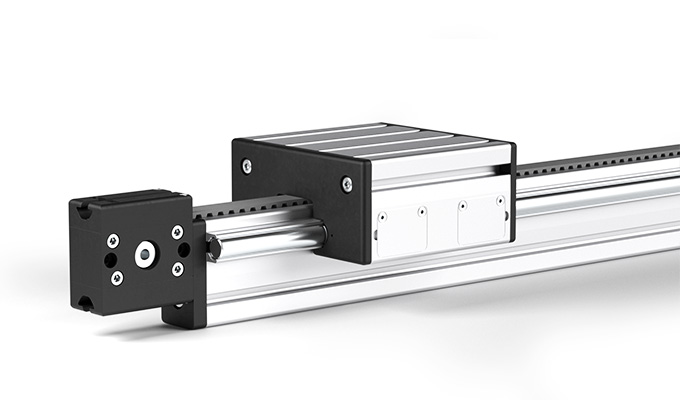

The linear axis system 16 is based on a large number of guide profiles with integrated shaft clamping, hardened and ground 16 mm steel shafts and different carriage profiles. In combination with appropriate toothed belt deflection systems, linear axes can be manufactured to customer specifications that meet the requirements for load, the use of multiple track rollers, as well as in terms of design.

- Sizes: 40 x 40, 40 x 80 / 40, 40 x 80 / 80, 80 x 80, 80 x 120, 80 x 120 8N, 120 x 120 / 80

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The toothed belt counter-reflections are manufactured for toothed belts AT 10/22 and AT 10/50. Counter-reversing devices allow the drive to be shifted from the end of an axis to the carriage. Thus, the carriage becomes a stationary element of the structure and the axis itself is moved. In our standard program we offer counter diverters with integrated carriages and counter diverters without carriages for special customer applications. Frequent use also for multi-axis systems.

- Sizes: Telescopic axle 16

40 x 80 / 80 + 40 x 80 / 80 / 200 / G 50

Linear axis 16

40 x 80 / 40 / G 22, 80 x 80 / G 50, 40 x 80 / 80 + 40 x 80 / 80 / G 50, 80 x 80 + 40 x 80 / 80 / G 50 - Drive variant: Toothed belt drive

- Guide variant: roller guide

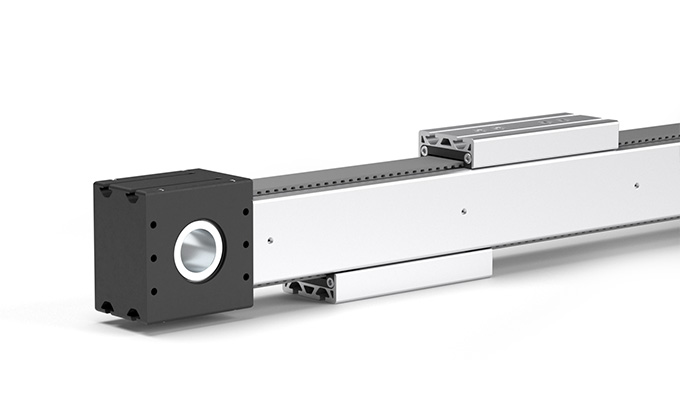

The Linear Axis System 25 is based on a large number of guide profiles with integrated shaft clamping, hardened and ground 25 mm steel shafts and various carriages. In combination with appropriate toothed belt deflections, linear axes can be manufactured according to customer requirements, which meet the demands for load, the use of several and different track rollers, as well as the requirements in terms of design.

- Sizes: 40 x 40, 80 x 80, 80 x 160, 120 x 120

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The internal 80 x 100 guide is guided by an internal 15-ball rail and the 120 x 150 guide by a 25-ball rail. The AT 10/22 timing belt is used in conjunction with the 40/40 timing belt reversal for the 80/100 guide profile, and the AT 10/50 timing belt is used in conjunction with the 80/120 timing belt reversal for the 120 x 120 guide profile.

- Sizes: 80 x 100, 120 x 150

- Drive variant: Toothed belt drive

- Guide variant: Ball rail guide

The internal double guide 120 x 150 is guided by two internal 15 ball rail guides. The system is driven by a toothed belt and is maintenance-free. To protect the internal guides against contamination, the profile is closed by the toothed belt. The AT 10/50 timing belt is used in conjunction with the 80 x 120 timing belt deflection for the 120 x 150 guide profile.

- Sizes: 120 x 150

- Drive variant: Toothed belt drive

- Guide variant: Ball rail guide

Single guide or double guide, can be operated at any angle due to its special roller guide and is maintenance free. The AT 10/50 timing belt is used in conjunction with the 80/90 or 80/80 timing belt reversing system. The double guide also offers pick-up options on both sides by means of two carriages.

- Sizes: 80/90 single guide, 80/90 double guide, 120×120 AT10/75 plastic rollers, 120×120 AT10/75 steel rollers

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The C linear axis system is based on a large number of guide and carriage profiles. Plastic rollers made of POM are used, which run directly in the aluminum profile. The corresponding deflection units for toothed belt drives are manufactured for the individual guide profiles. The timing belt reversers are manufactured for AT 3/10 and AT 5/16 and AT 10/22 timing belts. The motor is connected via a steel insert of your choice. The motor is mounted either directly or via a coupling or toothed belt drive. We manufacture the required flange plates or coupling bells according to your requirements.

- Sizes: C 40 x 57, C 40 x 100, C 80 x 100, C 80 x 100 Double Guide

- Drive variant: Toothed belt drive

- Guide variant: roller guide

C-guides with plastic rollers. Increasing the number of rollers increases the permissible load values of the system. C-guides do not require lubrication and are a cost-effective alternative to steel guides.

- Sizes: C 80 x 100 with counter deflection

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The linear axis system 16 is based on a large number of guide profiles with integrated shaft clamping, hardened and ground 16 mm steel shafts and different carriage profiles. In combination with appropriate toothed belt deflection systems, linear axes can be manufactured to customer specifications that meet the requirements for load, the use of multiple track rollers, as well as in terms of design.

- Sizes: 40 x 40, 40 x 80 / 40, 40 x 80 / 80, 80 x 80, 80 x 120, 80 x 120 8N, 120 x 120 / 80

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The toothed belt counter-reflections are manufactured for toothed belts AT 10/22 and AT 10/50. Counter-reversing devices allow the drive to be shifted from the end of an axis to the carriage. Thus, the carriage becomes a stationary element of the structure and the axis itself is moved. In our standard program we offer counter diverters with integrated carriages and counter diverters without carriages for special customer applications. Frequent use also for multi-axis systems.

- Sizes: Telescopic axle 16

40 x 80 / 80 + 40 x 80 / 80 / 200 / G 50

Linear axis 16

40 x 80 / 40 / G 22, 80 x 80 / G 50, 40 x 80 / 80 + 40 x 80 / 80 / G 50, 80 x 80 + 40 x 80 / 80 / G 50 - Drive variant: Toothed belt drive

- Guide variant: roller guide

The Linear Axis System 25 is based on a large number of guide profiles with integrated shaft clamping, hardened and ground 25 mm steel shafts and various carriages. In combination with appropriate toothed belt deflections, linear axes can be manufactured according to customer requirements, which meet the demands for load, the use of several and different track rollers, as well as the requirements in terms of design.

- Sizes: 40 x 40, 80 x 80, 80 x 160, 120 x 120

- Drive variant: Toothed belt drive

- Guide variant: roller guide

Single guide or double guide, can be operated at any angle due to its special roller guide and is maintenance free. The AT 10/50 timing belt is used in conjunction with the 80/90 or 80/80 timing belt reversing system. The double guide also offers pick-up options on both sides by means of two carriages.

- Sizes: 80/90 single guide, 80/90 double guide, 120×120 AT10/75 plastic rollers, 120×120 AT10/75 steel rollers

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The C linear axis system is based on a large number of guide and carriage profiles. Plastic rollers made of POM are used, which run directly in the aluminum profile. The corresponding deflection units for toothed belt drives are manufactured for the individual guide profiles. The timing belt reversers are manufactured for AT 3/10 and AT 5/16 and AT 10/22 timing belts. The motor is connected via a steel insert of your choice. The motor is mounted either directly or via a coupling or toothed belt drive. We manufacture the required flange plates or coupling bells according to your requirements.

- Sizes: C 40 x 57, C 40 x 100, C 80 x 100, C 80 x 100 Double Guide

- Drive variant: Toothed belt drive

- Guide variant: roller guide

C-guides with plastic rollers. Increasing the number of rollers increases the permissible load values of the system. C-guides do not require lubrication and are a cost-effective alternative to steel guides.

- Sizes: C 80 x 100 with counter deflection

- Drive variant: Toothed belt drive

- Guide variant: roller guide

The internal 80 x 100 guide is guided by an internal 15-ball rail and the 120 x 150 guide by a 25-ball rail. The AT 10/22 timing belt is used in conjunction with the 40/40 timing belt reversal for the 80/100 guide profile, and the AT 10/50 timing belt is used in conjunction with the 80/120 timing belt reversal for the 120 x 120 guide profile.

- Sizes: 80 x 100, 120 x 150

- Drive variant: Toothed belt drive

- Guide variant: Ball rail guide

The internal double guide 120 x 150 is guided by two internal 15 ball rail guides. The system is driven by a toothed belt and is maintenance-free. To protect the internal guides against contamination, the profile is closed by the toothed belt. The AT 10/50 timing belt is used in conjunction with the 80 x 120 timing belt deflection for the 120 x 150 guide profile.

- Sizes: 120 x 150

- Drive variant: Toothed belt drive

- Guide variant: Ball rail guide

Contact now

Always up to dateDo you have a question? A suggestion? Or an order? Don’t hesitate to get in touch with us. Whether by e-mail or with a phone call – our experts will be happy to help you with all aspects of aluminium profiles.